We briefly mentioned the 9 features of a quality impact traffic door in our article titled What are Impact Traffic Doors? Next we are going to discuss each feature in more detail. This is the first in our two-part series called “9 Must Have Features of Impact Traffic Doors”.

Single or double leaf Durulite door

The range of standard sizes allow architects and designers a free hand when they work on a commercial or industrial project. In addition, from the specification sheets you will note that single leaf and double leaf sets overlap each other slightly ito available dimensions. In other words, the widest single leaf impact door is wider than the narrowest double leaf impact traffic door. Double leaf sets outsells single leaf sets four to one.

Various sizes and colours

Single leaf Durulite impact doors

- leaf width 620 mm to 1 380 mm

- leaf height 1 980 mm to 3 050 mm

- frame width 770 mm to 1 530 mm

- frame height 2 055 mm to 3 125 mm

- 41 standard sizes to choose from

Double leaf Durulite impact doors

- leaf width 1 225 mm to 2 445 mm

- leaf height 1 980 mm to 3 050 mm

- frame width 1 375 mm to 2 595 mm

- frame height 2 055 mm to 3 125 mm

- 38 standard sizes to choose from

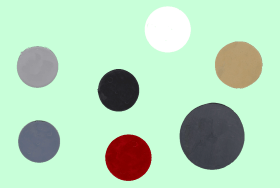

Three types of frames are available ie black powder coated, galvanized steel or stainless steel clad and you can choose from 7 colours:

Lightweight and durable

The secret of a good impact entry door lies in its weight and (ease of) operation. Belief it or not, if you made a door of solid lead, it would theoretically outlast Durulite doors. Although this may be true, the hinges won’t last a day. For this reason we see three interacting factors and a balance among them is critical:

- how much a leaf weighs

- how durable (or impact resistant) the leaf is, and

- ease of operation

The general thought in life is to increase weight to make something durable, right? Well, if you add too much weight to make it that durable, you will sacrifice smooth and easy operation plus longevity. Durulite doors are easy to use.

Good thermal insulation

The internal core of the leaf is injected with a closed-cell foam called Polyurethane. This is done primarily for insulation. Polyurethane is one of the best thermal insulation materials available today thanks to its low thermal conductivity. The injected Polyurethane foam, however, also assist with shock absorption and noise reduction of the leaf.

Summary

Every one of the features discussed here applies to every size, shape and colour Durulite doors we offer. Feel free to contact Strip Curtain Solutions to discuss your requirements for commercial impact doors. We look forward to hearing from you!

Link to part 2: 9 Must Have Features of Impact Traffic Doors (Part 2)